Failure Mode and Effects Analysis Template Help

Home » SPC for Excel Help » Statistical Tools » Correlation Help » Failure Mode and Effects Analysis Template Help

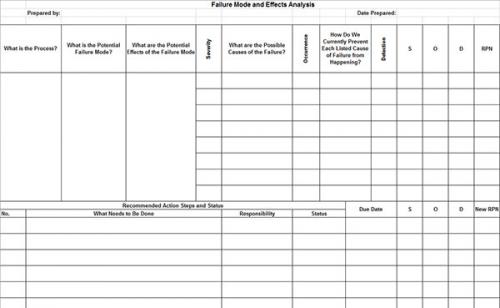

Failure Mode and Effects Analysis (FMEA) is an analytical way of identifying how a process can fail and the consequences of that failure. FMEAs are best used prior to implementing a new process or prior to modifying an existing process. This type of analysis is an organized way of discovering what could go wrong, and planning what we can do to eliminate such potential problems.

FMEAs evaluate three key dimensions of process failure; severity, occurrence frequency and detectability on a scale of 1 to 10 (1 lowest, 10 highest). Severity is a measure of how damaging a failure would be. Occurrence frequency tells us how often this type of failure might occur. A problem that occurs several times a day rates high on the occurrence scale while something that happens once every few years rates very low on the occurrence scale. Detectability is an estimate of how likely it is that you will detect the failure prior to its having a harmful effect. A failure mode that would be obvious for a long time prior to any harmful effects happening rates a low detectability score. Failure modes that are essentially undetectable prior to the effects taking place rate high on this scale.

To access the FMEA:

Select “Correlation” from the “Statistical Tools” panel on the SPC for Excel ribbon.

Select the “Failure Mode and Effects Analysis Template” option and then OK.

The template is added as new worksheet. The sheet is set up to automatically calculate the Risk Priority Number when the severity, occurrence, and detection ratings are entered. Some cells are protected. You can unprotect the worksheet since there is no password. If you want to add multiple lines in a cell, such as under the What are the Potential Effects of the Failure Mode, you enter a line, then hit ALT + Enter.