Process Capability Options in SPC for Excel

Easily see if your process is meeting customer specifications with SPC for Excel’s process capability techniques for normally and non-normally distributed data:

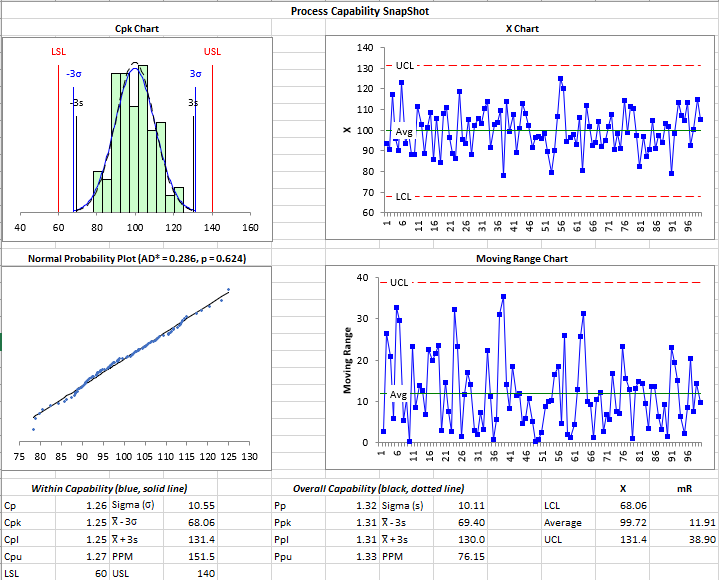

Normal Process Capability Snapshot

- Consists of Cpk chart, control chart (either X-R, X-s or X-mR), normal probability plot and select statistics

- Cpk chart: contains many of the options listed below

- Select Out of Control Tests for control chart

- Includes Anderson-Darling statistic and p value for normal probability plot

- Select statistics included at bottom of page

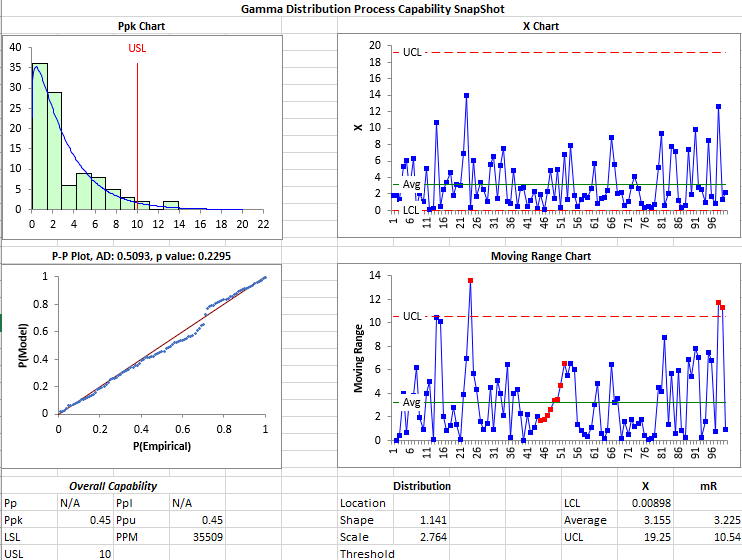

Non-normal Process Capability Snapshot

- Consists of Ppk chart, control chart (either X-R, X-s or X-mR), P-P plot to test the fit of the distribution and statistics

- Ppk chart: contains many of the options listed below

- Select out of control tests for control chart

- Includes Anderson-Darling statistic and p value for the P-P plot

- Select statistics included at bottom of page

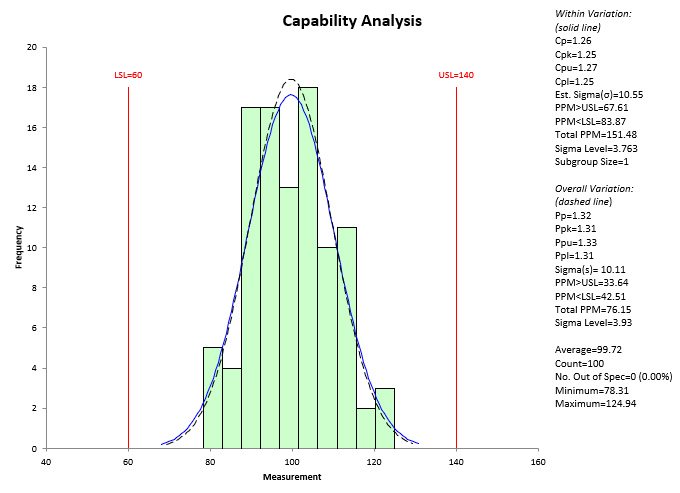

Normal Process Capability (Cpk/Ppk)

- Histogram

- Lower specification limit, nominal (if entered), upper specification limit (only one specification is required as the software handles one-sided specifications)

- Normal curve based on estimated sigma and/or calculated standard deviation

- +/- 3 sigma limits based on estimated sigma and/or calculated standard deviation

- Plot average

- Shade/unshade histogram option

- Confidence limits for Cpk and Ppk

- For subgroups, base estimate of sigma on average range, average standard deviation or pooled variance

- Output Statistics Options:

- Within Process Capability (based on estimated sigma)

- Overall Process Capability (based on calculated standard deviation)

- General Statistics

- Add target (to calculate Cpm)

- Option to remove outliers

- Option to use historical average and standard deviation in the calculations

- Option to transform the data with Box-Cox or Johnson transformations

- Add dates of data collection

- Change the number of classes, the class width or the starting point on the histogram

- Easily update with new data

- Process capability table to summarize all process capability charts in a workbook

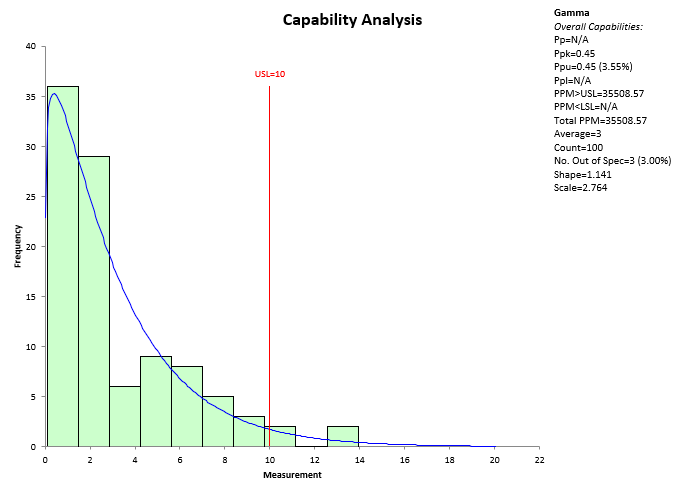

Non-Normal Process Capability (Ppk)

- Histogram

- Lower specification limit, nominal (if entered), upper specification limit (only one specification is required as the software handles one-sided specifications)

- Select one of 13 distributions for the analysis:

- Exponential

- Exponential - Two Parameter

- Gamma

- Gamma - Three Parameter

- Largest Extreme Value

- Logistic

- LogLogistic

- LogLogistic - Three Parameter

- LogNormal

- LogNormal - Three Parameter

- Normal

- Smallest Extreme Value

- Weibull

- Weibull - Three Parameter

- Option to enter the parameters for the distribution or have SPC for Excel find the best-fit parameters

- Option to plot average

- Option to shade the histogram

- Add dates of data collection

- Add titles and axis labels

- Add target to calculate Cpm

- Change the number of classes, the class width or the starting point on the histogram

- Easily update with new data

- Process capability table to summarize all process capability charts in a workbook

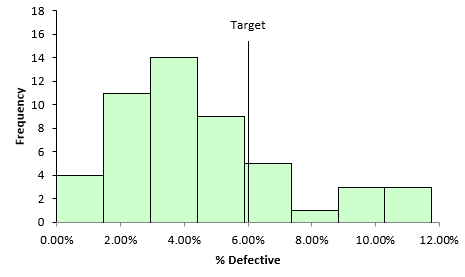

Binomial Capability

- Histogram

- Optional Target

- p Control Chart

- Select Out of Control Tests

- % Defective vs. Subgroup Size Chart

- PPM Defective

- Change the number of classes, the class width or the starting point on the histogram

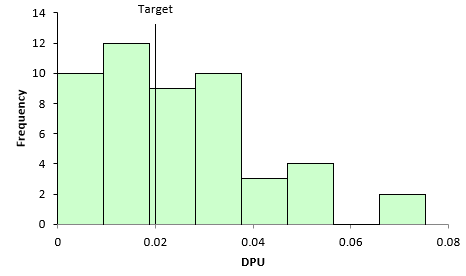

Poisson Capability

- Histogram

- Optional Target

- u Control Chart

- Select Out of Control Tests

- Cumulative DPU Chart

- DPU versus Subgroup Size Chart

- Change the number of classes, the class width or the starting point on the histogram