Complete Teaching Guides for Statistical Process Control

Home » Training & Consulting » Complete Teaching Guides for Statistical Process Control

The complete teaching guides we currently have available are:

C And U Control Charts Complete Teaching Guide

The purpose of this module is to introduce c and u control charts – what they are, when they can be used, how to construct them and how to interpret both charts. In addition, the small sample case for c and u control charts is introduced. The c and u control charts tell you if the process is in statistical control or if there are special causes present.

Exercises and examples include OSHA recordable injuries, emergency work orders in maintenance, customer complaints, hospital infections, assembly defects and plastic imperfections. The control limit equations commonly used for the c and u control charts are only valid under certain conditions. This module covers the “small sample case” and shows what to do when the control limit equations are not valid. Exercises include questions about what the charts are telling you about the process.

The module includes the following:

- Handout (25 pages)

- Teaching Guide (2 pages)

- Solutions to Exercises (10 pages)

- PowerPoint Presentation (41 slides)

- Excel Workbook Containing the Data

- Excel Workbook Containing the Solutions

To order:

Cause and Effect Diagrams Module

The purpose of this module is to introduce the cause and effect diagram – what it is, when to use it, how to construct, and how to analyze a cause and effect diagram. Creating a cause and effect diagram is enjoyable and educational. These diagrams are usually constructed as a team or group activity, in order to get ideas from as many people as possible. As a result of everyone contributing to the diagram, each person tends to gain some new knowledge.

Cause and effect diagrams introduce new ideas about the cause of problems by helping the group think about different categories of causes. The cause and effect diagram also helps to show how much we know about our process. If the diagram is full, we know a lot. If it is sketchy, chances are we don’t have a good understanding of our process. Cause and effect diagrams should not be idle documents. That is, we should continually search for the cause of problems, so that we may add to the diagram as time goes on.

The module includes:

- Handout (10 pages)

- Teaching Guide (2 pages)

- PowerPoint Presentation (21 slides)

To order:

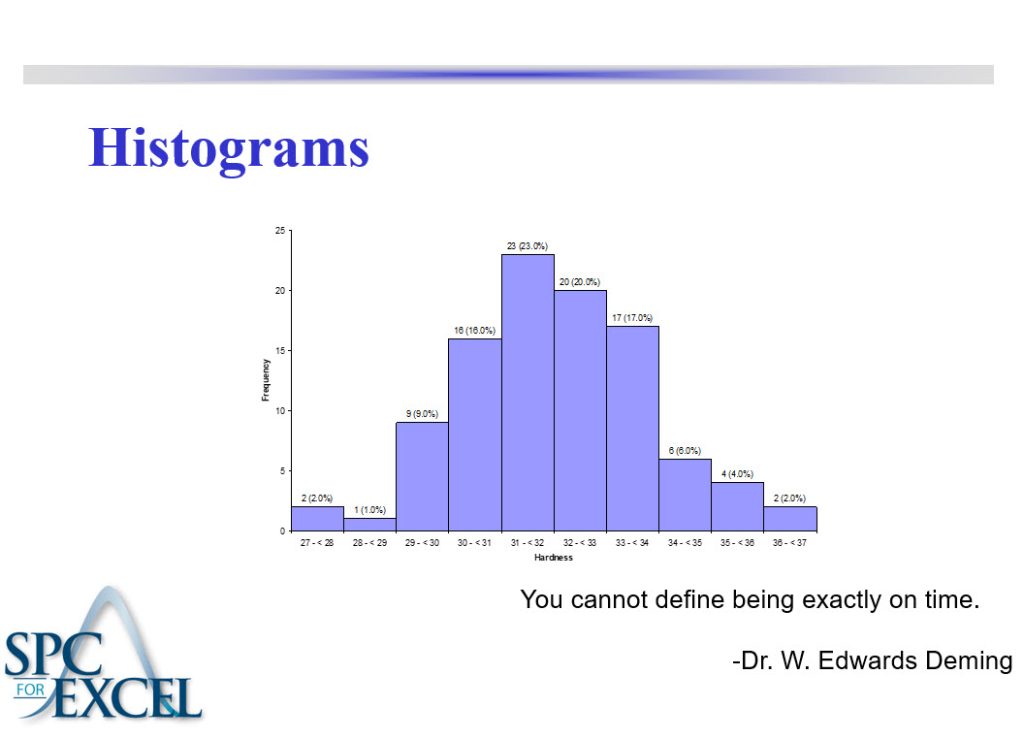

Histograms Module

A histogram is a picture of the history of your process. It helps answer the following questions:

- Which result (or range of results) occurs most frequently?

- How much variation is there about that result?

- What does the shape of the variation about that result look like?

- Are any results out of specifications?

A process is designed to produce a product or service. But in addition, the process produces data. You can use the data to improve the process. All processes have variation. Processes that are in statistical control (only common cause of variation present) tend to generate results that form a stable pattern. This pattern is called a distribution. Distributions are characterized by three parameters: location (average or typical value), spread (amount of variation) and shape (the pattern of variation – bell-shaped, symmetrical, etc.). These parameters of a distribution can be estimated by using a histogram.

The purpose of this module is to introduce the histogram. Control charts present a picture of how a process varies over time. Histograms, on the other hand, present a picture of how the process “stacks up” over time.

The module includes:

- Handout (19 pages)

- Teaching Guide (3 pages)

- Solutions to Exercises (7 pages)

- PowerPoint Presentation (33 slides)

- Excel Workbook Containing the Data

- Excel Workbook Containing the Solutions

To order:

Individual Control Charts Module

The purpose of this module is to introduce the individuals control chart – what it is, when to use it, how to construct and how to interpret an individuals control chart. The individuals control chart examines variation in individual sample results over time. It tells us if the process is in statistical control and gives us estimates of the process average and process standard deviation. We also examine how individual control charts can handle “chunky” data as well as rare events in this module.

Examples include accounts receivables past due 90 days, waiting in line at a bank, number of level 1 calls to IT, average yearly temperatures, and OSHA recordable injuries. Exercises include questions about what the charts are telling you.

The module includes the following:

- Handout (23 pages)

- Teaching Guide (3 pages)

- Solutions to Exercises (15 pages)

- PowerPoint Presentation (52 slides)

- Excel workbook containing data

- Excel workbook containing the solutions

To order:

Interpretation of Control Charts Module

A control chart represents a picture of a process over time. To effectively use control charts, one must be able to interpret the picture. What is this control chart telling me about my process? Is this picture telling me that everything is all right and I can relax? Is this picture telling me that something is wrong and I should get up and find out what has happened? This module presents various methods of interpreting a control chart.

The purpose of this module is to introduce the general model used for control charts, how control charts relate to a process, how to recognize a process in statistical control and the various tests for out of control situations. These out of control tests include points beyond the limits, the zones tests, tests for stratification and mixtures, and the rule of seven tests.

The module includes the following:

- Handout (17 pages)

- Teaching Guide (2 pages)

- Solutions to Exercises (4 pages)

- PowerPoint Presentation (28)

- Excel Workbook Containing the Example Data

To order:

P and Np Control Charts Module

The purpose of this module is to introduce p and np control charts – what they are, when they can be used, how to construct them and how to interpret them. The p and np control charts tell you if the process is in statistical control or if there are special causes present. These charts are used with yes/no type counting data – either an items meets a preset specification or it does not.

Exercises and examples include correct invoices, lines shipped complete from a supplier, orders expedited, and emergency work orders. The control limit equations commonly used for the p and np control chart are only valid under certain conditions. This module covers the “small sample case” and shows what to do when the control limit equations are not valid. Exercises include questions about what the charts are telling you about the process.

The module includes the following:

- Handout (35 pages)

- Teaching Guide (3 pages)

- Solutions to Exercises (9 pages)

- PowerPoint Presentation (42 slides)

- Excel Workbook Containing the Data

- Excel Workbook Containing the Solutions

To order:

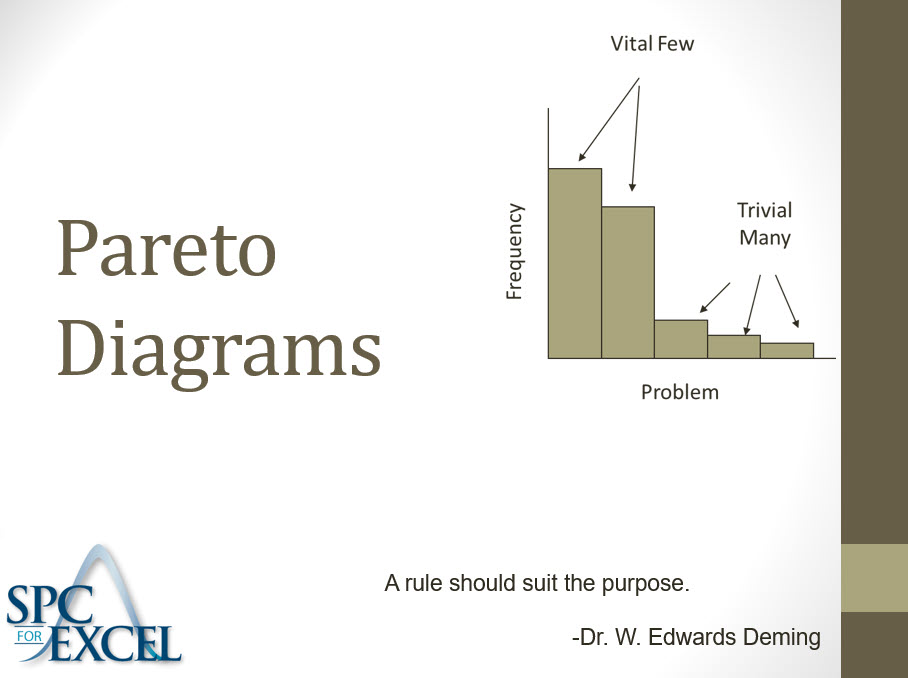

Pareto Diagrams

A Pareto diagram is a data-based approach to determine what the major problem or cause is. All companies have lots and lots of problems on which to work. There is not enough time in our day to work on everything. The Pareto diagram gives us a way to determine which problem to work on first – where we will get the most return for our investment.

The purpose of this module is to introduce the Pareto diagram – what it is, when to use it and how to construct a Pareto diagram. Vilfredo Pareto, an Italian economist, developed the Pareto diagram in the late 1800s. He discovered that 80% of Italy’s wealth was held by 20% of the people. This has become known as the 80/20 rule or the Pareto principle. It is at the heart of the Pareto diagram. The 80/20 rule applies in many places – 20% of our customers are responsible for 80% of the customer complaints; 20% of the workforce account for 80% of employee issues. The Pareto diagram is one method of separating that 20% – the vital few – from the 80% – the trivial many. This allows us to focus our time, energy, and resources where we will get the most return for our investment.

This module includes:

- Handout (16 pages)

- Teaching Guide (3 pages)

- Solutions to Exercises (3 pages)

- PowerPoint Presentation (41 slides)

- Excel Workbook Containing the Data

- Excel Workbook Containing the Solutions

To order:

Process Capability Module

The purpose of this module is to introduce process capability including the definition of process capability for attributes data, the definition of process capability for variables data, and how to calculate process capability (Cp, Cpk, Pp and Ppk). Exercises include determining the process capability for the hardness of steel tubes, the cut length of bars, and particle size distribution. How to determine the % out of specification is included.

The module includes the following:

- Handout (19 pages)

- Teaching Guide (3 pages)

- Solutions to Exercises (6 pages)

- PowerPoint Presentation (44 slides)

To order:

Variation Module

The purpose of this module is to introduce the concept of variation. It begins by defining quality. If we want to produce quality products and services, we must understand what a process is and why it is important that we focus on the process – not the end product or service. Variation is then defined. To reduce variation, it must be traced back to its source. In the past, variation has been handled through specifications. While specifications are important, they don’t really help improve a process. To improve a process, one must understand what common and special causes of variation are. Statistical control is introduced.

The module includes the following:

- Handout (17 pages)

- Teaching Guide (3 pages)

- Instructions for the Red Bead Experiment (5 pages)

- PowerPoint Presentation (34 slides)

To order:

Xbar-r Control Charts Module

The purpose of this module is to introduce the Xbar-R chart. This type of control chart is used with variables data – data that is taken along a continuum. Time, density, weight, and length are examples of variables data. Like most other variable control charts, it is actually two charts. One chart is for the subgroup averages (Xbar). The other chart is for the subgroup ranges (R).

The module includes explaining how the Xbar-R control chart works, how to construct the Xbar-R control chart and how to interpret the Xbar-R control chart. Examples and exercises included are golf, bag weights, water bottle volumes, and rationally subgrouping (three different plans) Exercises include questions about what the charts are telling you.

The module includes the following:

- Handout (24 pages)

- Teaching Guide (3 pages)

- PowerPoint Presentation (40 slides)

- Solutions to All Problems (15 pages)

- Excel workbook containing the data

- Excel workbook containing the solutions

To order:

Xbar-s Control Charts Module

The purpose of this module is to introduce the Xbar-s chart. This type of control chart is used with variables data – data that is taken along a continuum. Time, density, weight, and length are examples of variables data. Like most other variable control charts, it is actually two charts. One chart is for the subgroup averages (Xbar). The other chart is for the subgroup standard deviations (s).

The module includes explaining how the Xbar-s control chart works, how to construct the Xbar-s control chart and how to interpret the Xbar-s control chart. Examples and exercises included are bag weights, water bottle volumes, call center phone times, vaccine potency, bolt diameters, and supplier delivery performance. Exercises include questions about what the charts are telling you.

The module includes the following:

- Handout (19 pages)

- Teaching Guide (3 pages)

- PowerPoint Presentation (39 slides)

- Solutions to All Problems (15 pages)

- Excel workbook containing the data

- Excel workbook containing the solutions

To order: