SPC Blog

Home » SPC Blog

What is Evaluating the Measurement Process (EMP)?

It is time to replace the average/range method and ANOVA method for Gage R&R studies. Evaluating the Measurement Process (EMP)

It is Your Fault!

You are a front-line operator. Who gets the blame when something goes wrong? Far too often, you do – the

Dr. W. Edwards Deming and Profound Knowledge

Have you heard of Dr. W. Edwards Deming? Do you remember who he was? Dr. Deming was one of the

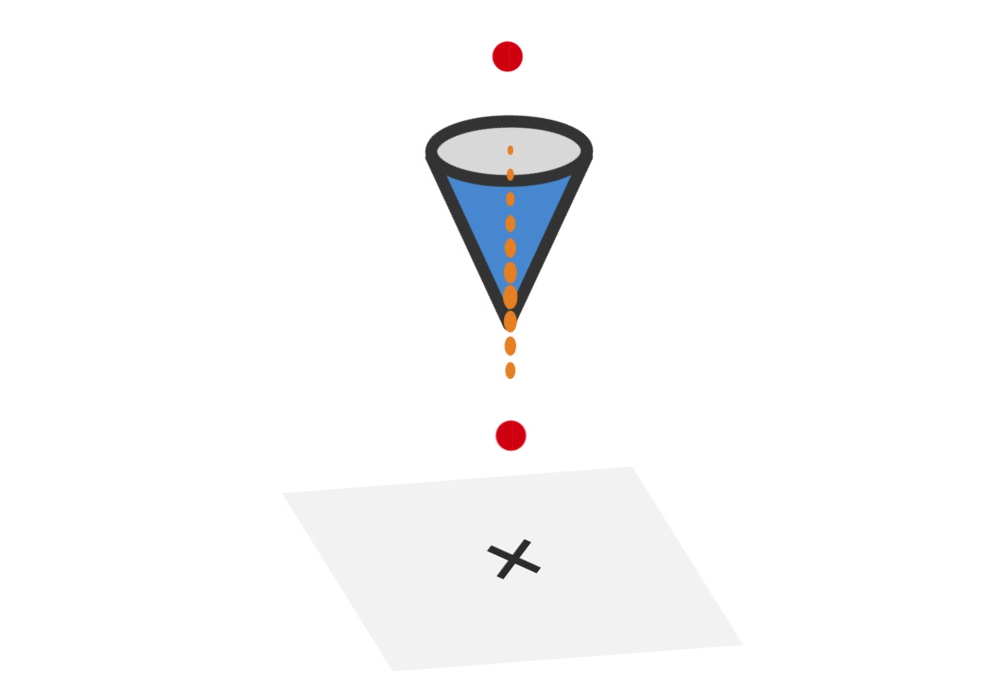

Variation and the Funnel Experiment

Our last blog, The Red Bead Experiment, described a simple process to teach variation to everyone. This blog describes another

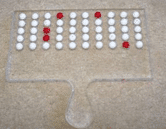

The Red Bead Experiment

Our last blog, A True Story about Variation, showed how leadership was blaming operators for process problems. They did not

A True Story About Variation

To really understand common and special causes of variation, many people must change their paradigm. The following is a true

Part 2: Are My Data Normally Distributed?

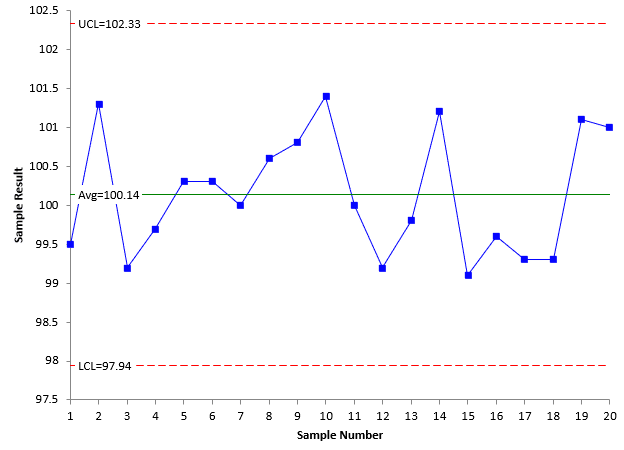

Our last blog – Are My Data Normally Distributed?– involved using a normal probability plot to answer that question. Essentially,

Are My Data Normally Distributed?

You have a set of data. You would like to know if the data comes from a normal distribution. How

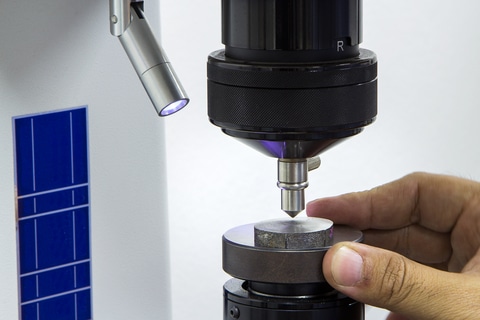

How Can We Trust Our Measurement Process?

Measurements tell us many things. They tell us if a product is within specification, if we met our goal, if