November 2013

Most of the time you are forced to take an in-depth look at a process is when there is a problem – something costing the company money or giving a customer a major headache. How do you approach a process to really develop an understanding of what is going on? This month’s publication takes a look at an approach for conducting a process analysis. The objectives of a process analysis are:

- To understand the steps in the process

- To discover existing and potential problems in the process

- To identify waste in the process

- To learn where the process should be measured

In this issue:

This publication can be downloaded as a pdf file at this link.

Our Process

Fairly simple process. Well, now a major customer is complaining about errors on their orders. Some orders have the wrong quantity – “we ordered 100 pairs of gloves and only received 98.” Other orders are missing line items completely – “we order 10 switches and the order didn’t contain any.

The warehouse manager has contacted you to help with the problem. After all, it is a quality “problem.” How would you approach this problem? Talk to the pickers to find out what the problems are? Tell them they need to do better – pay more attention? Start double-checking everything they pick? Is this even the most pressing problem you have in this process?

The first step in problem solving should always be to define and understand the process. That is the purpose of the process analysis. This can be done by one person or by a team. But the process always includes those closest to the process. And the warehouse manager doesn’t care what you do – she just wants a solution.

Process Analysis Steps

You cannot conduct a process analysis from your office. It just plain cannot be done. The only way to conduct a process analysis is to “walk” the process – from start to finish. So, step one in your process analysis is to define the starting point in the process and the ending point in the process.

Step 1: Define the Starting and Ending Points of the Process

Defining the first and last steps of a process sets the boundaries for the process. Do not take this step lightly. One of the biggest problems with a process analysis occurs if the scope is set incorrectly. The tendency is to set too large of a scope – too large of a process.

For example, maybe you believe that one on the reasons customers have problems with orders is that the salesperson enters the order wrong. The pickers pick it correctly, but the wrong item was sent. So, you might be tempted to set the starting point when the salesperson received the order. While you may have a valid point, the problem is that the customer is receiving wrong quantities or items missing from the order – all picking issues.

You decide to focus solely on the picking process. You set the starting point as when the order is printed in the warehouse supervisor’s office. The ending point is when the picker places the order at the packing table. You are now ready to “walk the process.” Well, almost.

Step 2: Explain the Process Analysis to Those Closest to the Process

Remember variation and the red bead experiment (click for our variation publications). Explain to those closest to the process exactly what you will be doing. Now, you are ready to “walk the process.”

Step 3: Walk the Process

You are now ready to get out of your office and walk the process from start to finish. “Walking the process” is just that. You begin at the first step of the process and go to the last step of the process. The key here is that you are interacting with the person doing the job – the picker. You cannot understand what is going on until you look through the eyes of the person doing the work.

Suppose that a picker named Mike is getting ready to pick an order. You get with Mike and watch him do the process from start to finish. As Mike is doing the work, you are recording his steps so you can make a detailed process flow diagram. The key here is to ask lots of open-ended questions – those questions that start with who, what, when, where and how. The goal to get this person’s insights and opinions about the process. Ask things like:

- How do you know that the item you are picking is the correct item?

- What do you do if there is a problem?

- Where do you find that out?

- How often does that happen?

- Who makes that decision?

- What causes you the most problems?

- When does that happen?

As you go through the analysis, you are looking for opportunities to improve the process as well as points where the process can be measured. Opportunities to improve the process include looking for areas of waste.

You cannot only talk to one person. You have to repeat this process with several people who are closest to the process. This does a number of things. First, it gives you different perspectives on what people think about the process, and why they do what they do. Second, it shows you the differences in the way people do the process.

Step 4: Construct the Process Flow Diagram

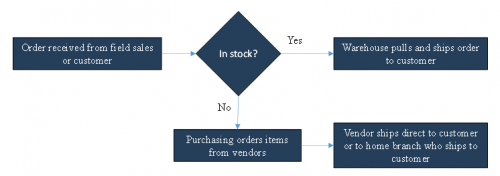

At this point, you are ready to construct the process flow diagram using the information you gathered from those closest to the process. This is a detailed process flow diagram – not an overview of the process. Figure 1 is an overview process flow diagram.

Figure 1: Overview Process Flow Diagram

This overview shows how an order is handled – but it is not very much use for problem solving. Note that your problem process is in the “warehouse pulls and ships order to customer” block. This sure doesn’t tell you what to do to improve the process.

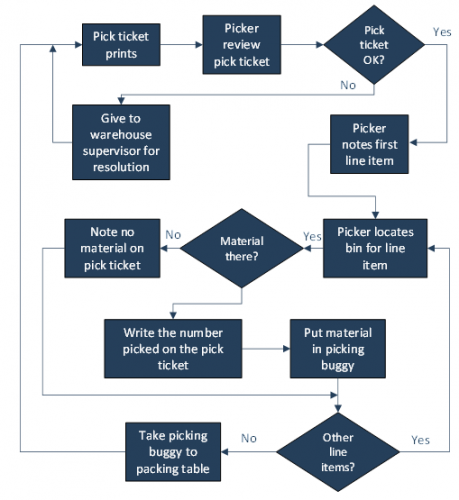

Figure 2 shows a process flow diagram that contains more detail. The one you make in reality will even be more detailed. But this is the only way to really understand the process.

Figure 2: More Detailed Process Flow Diagram

Once you have the process flow diagram, share it with those closest to the process – including those you talked to and those you didn’t. Make any revisions that are necessary.

Step 5: Determine Metrics and Opportunities for Improvement

Some of the opportunities are easy fixes, like moving the printer. Others may require a team to come up with a solution. You want to a have a list of these opportunities to present to leadership. Helping leadership to solve their problems will endear you to them – you will be like gold in their eyes.

You should have a list of metrics that can be used to monitor the process over time. These metrics should be designed to help give feedback to those closest to the process on how they are doing. The process flow diagram helps point out where measurements can be made. This is one advantage of doing a process flow diagram. It is also helpful to think about measuring a process in four dimensions: quality, quantity, timeliness and cost. Some possible measures for the picking process include:

- Picking accuracy: the % of line items picked correctly per picker and overall per day (as measured by the packers) – with a Pareto diagram on reasons for items picked incorrectly

- Average number of line items picked per hour per picker and overall

- Overtime costs for pickers per week

- Number of problems found at the time of picking

These metrics should be tracked in control chart format where appropriate. These charts will give the pickers and warehouse leadership the information they need to see how the picking process is behaving on a daily basis.

Step 6: Share the Process Analysis

You are ready to share your final results with leadership and with those closest to the process. Let them know what you found out and how you can help them improve the process. Be sure to thank those who gave you input for the process analysis.

Summary

This month’s publication examined how to conduct a process analysis using a simple picking process. The purpose of a process analysis is to develop a good understanding of what is going on in the process. From that understanding, you can help develop opportunities for improvement as well as metrics for the process. These metrics will track the process over time. Some processes will take much more work – worrying about sampling, measurement systems, etc. But that is all part of learning about the process. And you can’t do that until you get out of the office, away from your desk, and look at the process through the eyes of the person doing the work.

When the process analysis is done, the real work of process improvement can begin.

I have learnt good things and most important 1 is STEP:5 Determine Metrics and Opportunities

Quoting from the article: “Helping leadership to solve their problems will endure you to them – you will be like gold in their eyes”I hope rather that helping will “endear” you to those leaders. That would be a more pleasant outcome, wouldn’t it my dear?

Ha! Definitely meant "endear" – thanks for pointing that out. I changed it in the article.