February 2014

This month’s publication provides an overview to the Theory of Constraints (TOC). Part of TOC is built around a five-step focusing process that is designed to find and eliminate the constraints in your process. These constraints prevent you from getting more out of your process. TOC is a management philosophy based on the work of Eli Goldratt.

In this publication:

You can download a pdf copy of this publication at this link.

Eli Goldratt

Eli Goldratt was a physicist who became a management guru along the lines of Dr. W. Edwards Deming. The world became aware of TOC and Goldratt when the book, The Goal, was published in 1984. It was written by Goldratt and Jeff Cox. The subtitle of the book is “A Process of Ongoing Improvement.” This book took a different approach to teaching this process – it was written as novel. The main character is Alex Rogo, manufacturing plant manager. His advisor is Jonah. Jonah advises Alex by asking questions that help lead Alex to think about process improvement in a different way – both at work and in his personal life. This book should be on everyone’s “must read” list.

Goldratt wrote additional companion books over time including The Race, The Theory of Constraints, It’s Not Luck, and Critical Chain.

The Goal

We will only consider ‘for-profit” companies here. In reality, the goal of a company is one and only one:

To make money in the present as well as in the future

Goldratt said that every goal carries with it some necessary conditions that must be satisfied before the goal can be accomplished. For example, some potential necessary conditions “to make money in the present as well as the future” might be:

-

Quality

-

Competitive advantage

-

Technology leadership

-

Cash flow

-

Satisfied employees

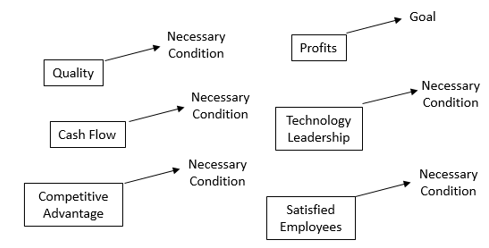

Without these necessary conditions, the goal of making money cannot be achieved. Goldratt believed that the goal and necessary conditions are interdependent. In the end, you have to have all of them to be successful as shown in the figure below.

Figure 1: Goal or Necessary Condition?

The Measurements

In addition to the goal, we need a set of measurements that will enable us to judge the impact of a local decision on the global goal of making money now and in the future. Typically, we can judge making money by:

-

Net Profit: – an absolute measurement (e.g., we made $2 million dollars last year).

-

Return on Investment: a relative measurement (e.g., we made $2 million dollars on the $20 million investment).

-

Cash Flow: a survival measurement (on-off type measurement; e.g.; when there is enough cash, it is not important, but when we don’t have enough cash, nothing else matters)

These three measurements are sufficient to determine if we are making money, but they are not adequate to judge the impact of our day-to-day actions on the goal. To help us judge the impact of our day-to-day actions on the goal, Goldratt defines three terms:

-

Throughput: the rate at which the system generates money through sales

-

Inventory: all the money that the system invests in purchasing things it intends to sell

-

Operating Expense: all the money the system spends in turning inventory into throughput

So, in terms of these three items, the global goal of “making money in the present as well as the future” becomes:

Increasing throughput while simultaneously reducing both inventory and operating expense

This becomes something people can use to determine how their local decision impacts the global goal. So what keeps us from reaching our goal?

Constraints

Constraints are what keep us from reaching the system’s goal. Goldratt said systems are like chains or networks of chains. Each event is dependent on the event in front of it. For example, final inspection can’t inspect the product until all the processing steps before it are completed. A bill can’t be paid until it is received and approved. All processes have dependency – one step must be done before another.

Consider the chain below. Suppose you pull on both ends. What will eventually happen if you continue to apply more force?

As you continue to apply more force, the chain will break. In how many places will the chain break? Only one – at its weakest link. This is a key concept in TOC. There is only one weakest link in chain. And it is this constraint (weakest link) that prevents the chain from being any stronger.

Suppose we fixed that weakest link — made it stronger. What happens now? The chain is stronger – but there is still a weakest link somewhere – something that constrains the strength of the chain.

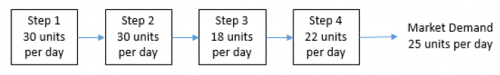

To take a closer look at constraints, consider the following simple four step process. This four step process produces a product that has a market demand of 25 units per day. We can sell 25 units each day. Figure 2 shows the capacity of each step.

Figure 2: Four Step Process

What is the maximum number of units produced each day? The maximum number of units produced is dictated by the constraint. In this example, that constraint is step 3, which produces only 18 units per day. This is the constraint in the process. Steps 1 and 2 each have a capacity of 30 units per day. What happens if they run at full speed? In-process inventory builds up in front of Step 3.

Suppose we work on Step 3 and improve its capacity to 35 units per day. How many units per day can we make? 22 units. Step 4 has become the bottleneck since its capacity is only 22 units per day. There will always be a constraint – a bottleneck. The challenge is to find it and do something about it.

Suppose we work on Step 4 and improve its capacity to 35 units. Now where is the constraint? The constraint has now moved from our internal process to an external process – market demand. The only way to sell more product is to increase market demand.

The Focusing Process

-

What to change, i.e., where is the constraint

-

What to change to, i.e., what should we do with the constraint?

-

How to cause the change, i.e., how do we implement the change?

There is a five step focusing process in TOC that helps us manage the change. The five steps are:

-

Identify the system constraint

-

Decide how to exploit the constraint

-

Subordinate everything else to the above decision

-

Elevate the constraint

-

Go back to step 1, but beware of “inertia”

We will look briefly at each of these steps.

Identify the System Constraint

As mentioned earlier, the strength of a chain is determined by its weakest link. You want to determine how to strengthen the chain. So what do you do first? You identify that weakest link. This is the constraint, the bottleneck. It is what prevents the company from obtaining more of the goal over time. You have to examine the flow of work through the company to find the constraint.

Decide How to Exploit the Constraint

Subordinate Everything Else to the Above Decision

After exploiting the constraint, what do we do? We want to align the entire company to support the above decision. In throughput, linkages are important. If you do something to one link, it will impact what happens in other links.

Suppose one person (Bob) can make 200 units per hour. However, this person supplies a person (Sam) who is the constraint. Sam can make only 100 units per hour. How many units should Bob make? If Bob works at his capacity of 200 units per hour, it will not take very long for him to overburden Sam, who can only make 100 units per hour. We must take action to ensure that the constraint is not overburden. So Bob should make much less than he is capable of making.

Elevate the Constraint

Now, suppose that we have done steps 1 through 3 but the constraint still exists. What do we do next? We do whatever is necessary to make the constraint stronger. Here elevate means increase the capacity of the constraint. It often involves changing the way the constraint is used.

If the constraint is a physical resource, it could mean adding shifts at the constraint or outsourcing work. If the constraint is a policy, it might mean making a change, e.g., elimination of the no overtime policy. This could include the purchase of more capital equipment – again this is a last resort.

In this step, we take whatever actions are necessary to eliminate the constraint — the constraint no longer exists after this step.

Go back to Step 1, but Beware of “Inertia”

We have now elevated the constraint. What happens to the throughput in the system? It will improve. Suppose we continue to elevate the constraint. What happens to the throughput? Eventually, the throughput will not increase because this constraint is no longer the weakest link. Continuous improvement means that we now begin the search for the new constraint and go back to step 1.

But what about inertia? In physics, inertia is the tendency for an object to remain at rest or in motion until it is acted upon by an outside force. At work, we often work on solving problems. But we have a tendency to forget about a problem once we have solved it. We assume it stays solved – that is until it raises its head in the same or another form.

Remember that processes are like chains – they are interdependent. Changes we make to future constraints may impact what we did with this constraint. So, we may need to re-examine old solutions to see the impact of our new solutions. Note that using SPC control charts to monitor old constraints are a great way to see quickly if something is changing. So simple!

Categories of Constraints

-

Market constraints are external constraints. A market constraint exists if you could sell more products than you currently do or serve more customers than you currently have.

-

Resource constraints are internal. Examples include bottlenecks, long lead times, rework, and quality issues.

-

Material constraints are usually external. A material constraint exists when a raw material issue keeps us from producing more.

-

Supplier constraints are external. These exist when our throughput is hurt by unreliable suppliers. This includes on-time delivery issues and the quality of the material provided.

-

Financial constraints are internal. These exist when there is no sufficient cash to meet short-term commitments or to upgrade facilities needed to increase throughput.

-

Knowledge or competence constraints are usually internal. They exist when we don’t have the knowledge to increase throughput – which could include moving into new industries.

-

Policy constraints are internal. These exist when a policy limits what we can do with throughput. It could be as simple as a mindset – we have always done it this way. These are often the most difficult to identify.

Summary

This month’s publication has taken a look at the Theory of Constraints, which is based on a management philosophy developed by Eli Goldratt. He defines the goal of any “for-profit” company as “making money in the present as well as the future.” To help make local decisions that are consistent with this goal, he restates the goal as “increasing throughput while simultaneously reducing both inventory and operating expense.”

To achieve the goal, we must remove the things that constrain our process. To do this, Goldratt introduced the five step Focusing Process to help identify and remove constraints in our processes. A key thing to remember is that the steps in a process are dependent, much like the links in a chain. What you do in one step may well affect other steps. Different categories of constraints were also introduced.

Education

Dr BillAs a CI guy, I have been looling to lessons from Goldratt and others to see the relationships and approach of our President and his team to the recent Virus situation.Have you or any of your associates discussed the GOAL, its lessons and steps to the actions to save our nation GOAL is human life is it not?

No, I have not discussed the GOAL in terms of the recent virus situtation -might be interesting to see waht Goldratt.com has to say about it.