December 2009

Happy New Year! It is hard to believe that this marks the end of the 6th year of publishing our monthly SPC newsletter. This is the 72nd newsletter and our readership has grown to over 6500. A special thank you to all our readers.

As 2009 draws to a close, it is time to review our past newsletters. This will help new readers know and remind our long-time readers what is available. Remember special and common causes of variation? How about the contributions of Dr. W. Edwards Deming? Questions on when to use a certain control chart or what the difference is between variable and attribute control charts? How can a histogram be used to monitor incoming material from a supplier? How do I know if my measurement system is any good? What is process capability and how do I determine it? How do I get to root cause? How do I know if these three processes are the same? All this information and much more is in our newsletters.

The newsletter topics have been divided in the following sections:

- Variation

- Dr. W. Edwards Deming

- Control Charts

- Variable Control Charts

- Attribute Control Charts

- Control Chart Examples

- Bar Charts: Paretos and Histograms

- Measurement Systems Analysis

- Process Capability

- Root Cause Analysis

- Comparing Processes

- Miscellaneous

- Feedback

- Quick Links

One of our objectives has been to make the website a place where people can go for information on SPC and related topics. We believe our newsletters have helped us reach this objective. There is a wealth of information in these newsletters. We hope you enjoy the review.

All the newsletters, sorted by category, can be accessed at this link.

Happy New Year to each of you and may 2010 be a wonderful year for you and yours!

Variation

- Variation (January 2004)

- Leadership and Variation (February 2004)

- Revisiting Variation (March 2006)

- Overcontrolling a Process: The Funnel Experiment (July 2006)

- Revisiting Variation (January 2008)

- The Red Beads: Understanding Variation (February 2009)

Dr. W. Edwards Deming

Dr. Deming spent years developing a theory for helping companies move forward into the twenty-first century. Remarkably, it all still applies today. Understanding Dr. Deming begins with understanding his “system of profound knowledge.” This system is composed of four bodies of knowledge:

- Knowledge of a system

- Knowledge of variation

- Theory of knowledge

- Knowledge of psychology

To understand the system of profound knowledge, you must understand what a system is and what the “aim” of a system is. You must also understand variation and realize that the true benefit of this understanding comes from how you lead people. You must understand the theory of knowledge, and finally you must understand motivation and psychology. You don’t have to be an expert in each of these areas. However, you must know something about each area because they are interrelated. Our four-part series addresses each of the bodies of profound knowledge:

- Dr. Deming and Profound Knowledge – Part 1 (October 2006)

- Dr. Deming and Profound Knowledge – Part 2 (November 2006)

- Dr. Deming and Profound Knowledge – Part 3 (December 2006)

- Dr. Deming and Profound Knowledge – Part 4 (January 2007)

Control Charts

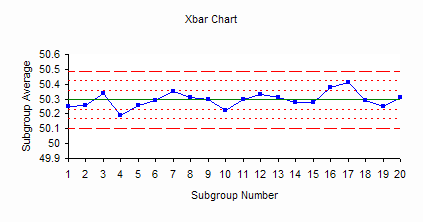

Control charts, of course, are the workhorse of statistical process control and represent the topic of many of our newsletters. A control chart is a movie of your process over time. It is the way that your process communicates with you. The control chart will tell you if everything is working as the process was designed (just common cause variation present) or if there is a problem (special cause variation present). All you have to do is listen.

To listen, you must be able to interpret a control chart. This was the first of our newsletters on control charts. The newsletter on control strategies provided a method of looking for the causes of out of control points. The January 2005 newsletter covered how to start and maintain control charts as well as provided insights on what should be charted. The newsletter on the impact of statistical control explains why calculated values of an average, a standard deviation, or a Cpk value have no meaning unless the process is in statistical control. The April 2006 newsletter provided a process flow diagram for selecting the right control chart to use. Our general control chart newsletters are listed below.

- Interpreting Control Charts (April 2004)

- Control Strategies (August 2004)

- Use of Control Charts (January 2005)

- The Impact of Statistical Control (February 2006)

- Selecting the Right Control Chart (April 2006)

Variable Control Charts

Variable control charts are used when you have variables data – data that you can measure to any precision (depending on your measurement system). Examples of variables data include height, weight, density and time. We have covered three variable control charts: Xbar-R, Xbar-s and the individuals (X-mR) control charts. Rational subgrouping is important when using Xbar-R and Xbar-s control charts. There are two newsletters that cover rational subgrouping along with a great exercise that shows the impact of rational subgrouping. In addition, we demonstrated how individuals control charts can be used to handle “rare” data as well as “chunky” data. Our variable control chart newsletters are listed below.

- Xbar-R Charts – Part 1 (March 2005)

- Xbar-R Charts – Part 2 (April 2005)

- Rational Subgrouping and Xbar-R Charts (May 2005)

- Rational Subgrouping and Xbar-R Charts – Part 2 (June 2005)

- Individuals Control Charts (October 2006)

- Chunky Data and Control Charts (April 2007)

- Rare Events and X-mR Charts (May 2007)

- Xbar-s Control Charts – Part 1 (September 2008)

- Xbar-s Control Charts – Part 2 (October 2008)

Attribute Control Charts

- c Control Charts (July 2004)

- p Control Charts (July 2005)

- u Control Charts (July 2007)

- Small Sample Case for p and np Control Charts (February 2008)

- Small Sample Case for c and u Control Charts (March 2008)

- np Control Charts (March 2009)

- Attribute Control Charts (April 2009)

Control Chart Examples

We have seven newsletters that describe how to use control charts in specific industries or situations:

- Monitoring Customer Complaints Using SPC (June 2006)

- SPC and On-Time Performance (June 2007)

- SPC & Process Improvement in the Warehouse (August 2007)

- SPC and Customer Service (November 2008)

- An Example of the Misuse of SPC in Health Care (August 2009)

- SPC and Pharmaceutical In-Process Control (September 2009)

- SPC and Pharmaceutical Finished Product Quality Specifications (October 2009)

Bar Charts: Pareto and Histograms

The Pareto diagram and the histogram are often referred to as bar charts. The Pareto is used to separate the “vital few” from the “trivial many” problems or causes. Histograms are used to estimate the location, spread and shape of a set of data. Our second part on the histogram newsletters showed how you can use histograms to monitor incoming material from suppliers.

- Pareto Diagrams (June 2004)

- Histograms – Part 1 (December 2005)

- Histograms – Part 2 (January 2006)

Measurement Systems Analysis/Gage R&R

- Operational Definitions/Measurement System Analysis (March 2004)

- Monitoring Test Methods Using SPC (May 2006)

- Variables Measurement Systems – Part 1: Stability (September 2007)

- Variables Measurement Systems – Part 2: Bias (October 2007)

- Variables Measurement Systems – Part 3: Linearity (November 2007)

- Variables Measurement Systems – Part 4: Gage R&R (December 2007)

- Measurement Systems – Is Yours Any Good (November 2009)

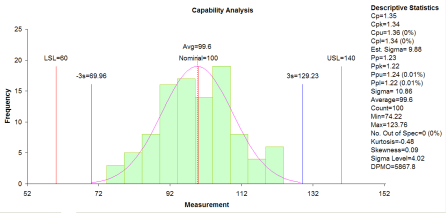

Process Capability

“Is the process capable of meeting specifications?” This is the key question that must be asked in the end. Does the process really do what we want it to? This is the issue of process capability and involves terms such as Cpk and Ppk. Our three-part series on process capability provides an in-depth explanation of process capability.

- Process Capability – Part 1 (October 2004)

- Process Capability – Part 2 (November 2004)

- Process Capability – Part 3 (December 2004)

Root Cause Analysis

One major aspect of problem solving is root cause analysis. What caused the problem to occur? How do we know it is the true cause of the problem? Our newsletters cover scatter diagrams to see if one variable is linearly correlated to another. Also included is how to create and analyze cause and effect (fishbone) diagrams. The Failure Mode and Effect Analysis newsletters resulted in the most visits to our website. We also have looked at modeling a process using linear regression. ANOVA was introduced in our December 2008 newsletter.

- Scatter Diagrams (February 2005)

- Creating Cause and Effect Diagrams (October 2005)

- Analyzing Cause and Effect Diagrams (November 2005)

- Failure Mode and Effects Analysis (May 2008)

- Linear Regression – Part 1 (June 2008)

- Linear Regression – Part 2 (July 2008)

- Single Factor ANOVA (December 2008)

Comparing Processes

On occasion, you have the need to compare two or more processes. Are the processes operating at the same average? With the same variance? The newsletters listed below describe how this can be done.

- Comparing Two Processes (August 2006)

- Paired Sample Comparison (September 2006)

- Comparing Multiple Processes (February 2007)

- Box and Whisker Plots (March 2007)

- Comparing Multiple Processes: Bonferroni’s Method (January 2009)

- Bartlett’s Test for Equality of Variances (July 2009)

Miscellaneous Topics

We also have offered a variety of miscellaneous topics. These include an explanation of standard deviation as well as skewness and kurtosis. A ten-step problem solving model, a method for data collection and a model for process management have been covered. The normal distribution and how to make a normal probability plot have also been introduced in our newsletters.

- Problem Solving Model (May 2004)

- Data Collection (September 2004)

- Explaining Standard Deviation (August 2005)

- Inspecting Supplier Material (September 2005)

- Process Management Model (November 2006)

- Are the Skewness and Kurtosis Useful Statistics? (April 2008)

- Normal Distribution (May 2009)

- Normal Probability Plots (June 2009)

Feedback

We have reviewed our on-line newsletters and hope you find this information useful. If you have any comments about our newsletters or have suggestions for future topics, please let us know.