February 2018

(Note: all the previous SPC Knowledge Base in the variation category are listed on the right-hand side. Select this link for information on the SPC for Excel software.)

Suppose you have a production goal of 100 units per month. This report looks at your results for the month. Two possible outcomes: either you made the goal or you didn’t. You are either happy – you made the goal – or unhappy – you didn’t make the goal. Sometimes that monthly report throws in other numbers – like your year-to-date production and how that compared to the year-to-date goal. Or maybe the monthly report compares this year-to-date result with the last year-to-date result.

What happens if you meet or exceed the goal? Everything is great. Move on to the next topic. Wait a minute! No discussion on how to improve the result? No, we reached the goal. That is all that matters.

And what happens when you don’t reach the goal? You are not so happy. You must find a reason why the goal was missed. Do you find a reason why the goal was missed? Of course, you do. Maybe even several reasons.

It is simply amazing that this form of reporting continues to be used in so many companies. This type of reporting includes no discussion at all about how the results may be changing over time. No looking at the underlying process. And no discussion at all about the month’s result being due to common causes of variation (the normal variation in a process) or due to special causes of variation (a signal that something has changed).

This publication looks back at variation using control charts and goals. These represent two totally diverse ways of looking at variation. In this issue:

- Your Job and Your Goal

- The Background Data

- The Monthly Results vs. the Goal

- The Goal Approach to Variation

- Common and Special Causes of Variation

- The Control Chart Approach to Variation

- How to Improve the Process

- Summary

- Quick Links

Please feel free to leave a comment at the end of the publication. You can download a pdf copy of this publication at this link.

Your Job and Your Goal

You are a production worker. You work on a machine that produces one part for multiple customers. That is your job according to management. Keep the machine running and make the parts. So simple. Of course, management is there to help you. They have given you a goal. To management’s credit, they looked at past data and, based on their analysis of the data, set the goal at 500 pieces per hour on average when the machine is scheduled to run. The goal is a monthly goal.

But management also believes in continuous improvement. They want the output to increase, of course. More parts, more sales, more profit. But how do you do that? Naturally, management thinks they know how to do that. Offer the workers a financial incentive. After all, everyone is motivated by money. Management offers a bonus of 2% per hour if you increase production to 510 pieces per hour and 4% per hour if you increase production to 525 pieces per hour.

Management had a meeting with you and your co-workers to review this new incentive. This incentive applies to all the workers on this machine, so the average of all workers has to be 500 pieces per hour. After all, you are a team!

The Background Data

To simulate the production, the random number generator in Excel was used to generate a population of 5000 numbers with an average of 500 and a standard deviation of 15. These 5000 results represent the average pieces produced per month on the machine. The average of these 5000 results was 500.138 and the standard deviation was 15.04. The random number generator was used to create a process that is stable – in statistical control.

12 results were picked at random from these 5000 to represent the data that management looked at to set the baseline. That data are shown in Table 1.

Table 1: Historical Data Used by Management

| Month | Pieces per Hour | Month | Pieces per Hour | |

|---|---|---|---|---|

| Jan-16 | 533 | Jul-16 | 489 | |

| Feb-16 | 493 | Aug-16 | 499 | |

| Mar-16 | 527 | Sep-16 | 510 | |

| Apr-16 | 469 | Oct-16 | 504 | |

| May-16 | 516 | Nov-16 | 494 | |

| Jun-16 | 520 | Dec-16 | 501 |

The average of these data is 504. Based on these results, management set the goal at 500 pieces per hour.

The Monthly Results vs. the Goals

You and your co-workers know your goal (500 pieces per hour) and your incentive goals (510 or 525 pieces per hour). The work progresses during January of the new year. At the end of the month, you receive the monthly production report. You and your co-workers averaged 473 pieces per hour. Management showed you a running total each day. It was clear early in the month that the target would not be reached – and the incentive goals were way off.

Management wants to know why the goal was not reached in January. They expect you to come up with a reason or two for why you missed the target. You find reasons, of course, to satisfy management’s questions. Maybe a key component on the machine broke or an experienced worker was on vacation for a week and you had to replace him with someone less experienced. But, you find your reasons.

The month of February rolls in and you feel things are going well on the machine. There are few problems. The monthly production report for February shows 514 pieces per hour. You exceeded the goal and reached the first incentive goal of 510 pieces per hour. A little more pay in the next paycheck. Management tells you what an excellent job you did.

Note there is one question that management does not ask you. And that question is:

“What did you do differently this month to reach the incentive goal?”

Everyone is just happy you reached the goal. All is well. No reason to go into the details. But the reality is, most likely, that you didn’t do anything different this month. You will probably have the same issue of finding reasons why you exceeded the first incentive goal as you do for finding reasons that you didn’t make the goal in January.

The months roll on by. The results for the year are shown below.

Table 2: Results

| Month | Pieces per Hour | Month | Pieces per Hour | |

|---|---|---|---|---|

| Jan-17 | 473 | Jul-17 | 505 | |

| Feb-17 | 514 | Aug-17 | 503 | |

| Mar-17 | 506 | Sep-17 | 493 | |

| Apr-17 | 490 | Oct-17 | 516 | |

| May-17 | 509 | Nov-17 | 517 | |

| Jun-17 | 484 | Dec-17 | 495 |

For the year, you and your co-workers missed the goal 5 times and each time had to explain to management why the goal was missed. You and your co-workers made the goal 7 times and three of those times reached the first incentive goal. 7 times you didn’t have to explain anything to management. You and your co-workers never reached the second incentive goal.

A year passed and focusing on the goal does not seem to have produced any lasting improvement. Why is that? Because the focus is wrong. A goal is not wrong. You must have goals to know where you are going. But you don’t reach the goal by focusing on it. You must focus on the process. Let’s compare the two different approaches to process improvement.

The Goal Approach to Variation

How do we typically try to handle variation? With products, we often use specifications. A product is good if it is within specification. This good product can be shipped to the customer. A product is bad if it is out of specification. This bad product has to be reworked or scrapped – or maybe shipped to a customer anyway. So, variation is divided into two parts:

Acceptable product: Within specifications

Unacceptable product: Outside specifications

This is the same approach that is used with goals.

Acceptable performance: Met the goal

Unacceptable performance: Missed the goal

This approach to performance (and to variation) leads to a binary view of the world: either everything is great (the goal was met) or everything is bad (the goal was not met, and you are “in trouble”).

This binary approach to performance focuses on the result – not on the underlying process that generated the result. This is the biggest problem with the goal approach to performance. It does not look at the underlying process. We need to change our focus from the result and the goal to what is happening in the underlying process. How do we do that? We must change our paradigm of variation from a binary view of the world to what is happening in the real world. We must look at results coming from common or special causes of variation. This is the only way to know what must be done to improve a process.

Common and Special Causes of Variation

Of course, goals are important, just like product specifications. But performance versus a goal doesn’t tell you what to do to improve a process. This is from our first publication back in January 2004 (with a few edits).

Variation comes from two sources, common and special causes. Think about how long it takes you to get to work in the morning. Maybe it takes you 30 minutes on average. Some days it may take a little longer, some days a little shorter. But if you are within a certain range, you are not concerned. The range may be from 25 to 35 minutes. This variation represents common cause variation — it is the variation that is always present in the process. And this type of variation is consistent and predictable. You don’t know how long it will take to get to work tomorrow, but you know that it will be between 25 and 35 minutes if the process remains the same.

Now, suppose you have a flat tire when driving to work. How long will it take you to get to work? Definitely longer than the 25 to 35 minutes in your “normal” variation. Maybe it takes you an hour longer. This is a special cause of variation. Something happened that was not supposed to happen. It is not part of the normal process. Special causes are not predictable and are sporadic in nature.

Why is it important to know the type of variation present in your process? Because the action you take to improve your process depends on the type of variation present. If special causes are present, you must find the cause of the problem and then eliminate it from ever coming back, if possible. This is usually the responsibility of the person closest to the process.

If only common causes are present, you must FUNDAMENTALLY change the process. The key word is fundamentally — a major change in the process is required to reduce common causes of variation. And management is responsible for changing the process.

It has been estimated that 94% of the problems a company faces are due to common causes. Only 6% are due to special causes (that may or may not be people related). If you always blame problems on people, you will be wrong at least 94% of the time. It is the process most of the time that needs to be changed. Management must set up the system to allow the processes to be changed.

So, Mom, sorry. But most of the time, spilling the milk was not my fault. It was usually yours (management). The glasses were too big for my small hands (no spill-proof cups in those days). When I wanted to put it by the edge of the table to make it easier to reach, you said move it back – I might spill it. And with the meal-time conversation, how could I concentrate on my milk!

You need to know what is due to common causes of variation and what is due to special causes of variation. So how do you separate common from special causes of variation? The only effective way to do this is by using control charts. The monthly report and goals do not do this!

The Control Chart Approach to Variation

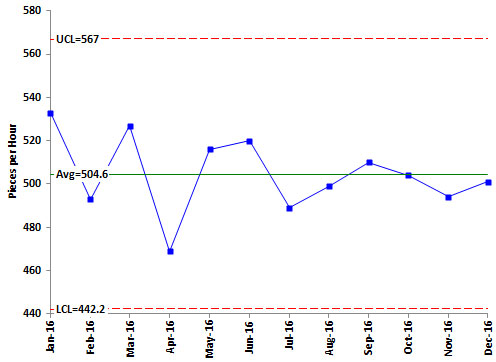

The first mistake management made was not to consider the state of the process that generated its historical data. Is the process consistent and predictable? Figure 1 is the control chart based on the historical data in Table 1. The individuals control chart is used. The moving range chart is not included in this analysis.

Figure 1: Historical Data Control Chart

The data are in statistical control. The production process is stable. On average, the process will produce 504.6 pieces per hour. Some months it may be as high as 567; other months it may be as low as 442. This represents the normal variation in the process.

Management’s estimate of the average then is not far off. And the process seems to be stable, so it is a “good” average. Management was lucky – the data was setup to come from a stable process in this example. The next mistake management made was in how to improve a process. They assumed that the workers could increase production if they just worked harder and faster, paid more attention, and so on. And the best way to do that, from management’s viewpoint, was to provide a financial incentive.

Here is the problem with that. The workers seldom control enough in their own work environment to make a significant and sustainable change. How many companies allow workers to change the work instructions, whenever they want to, without asking anyone or going through a new revision? Not many with all the audits companies face today.

A publication in our SPC Knowledge Base talks about variation, people, pay and performance. It addresses four assumptions that are often wrong:

- All people are motivated by money.

- We can use an incentive system to effectively motivate someone to do the job we want them to.

- There is a fair way of determining how much someone gets paid based on the work done by the individual.

- People have control of the system.

Dr. W. Edwards Deming pointed out that it is impossible to separate out the contribution of an individual or team to the process’s output from the contribution of the system. For example, let Z be the pieces per hour we are interested in measuring and rewarding a person or team on. Let X be the contribution of you or your team to the process output. Let Y be the contribution of the system to the process output. By system, we mean the processes involved in production, the type of supervision, the layout of the plant, etc. The equation for pieces produced is then

X + Y = Z

What is the workers contribution to that? The equation above cannot be solved for a unique value of X or Y. It is impossible to separate the two.

So, the idea the incentive goals will magically work is incorrect. The workers work in the system. If the process is in control, the workers are performing the best they can for the current system. The only way to improve is to work on the system – which is management’s responsibility – and that means to fundamentally change the process.

How to Improve the Process

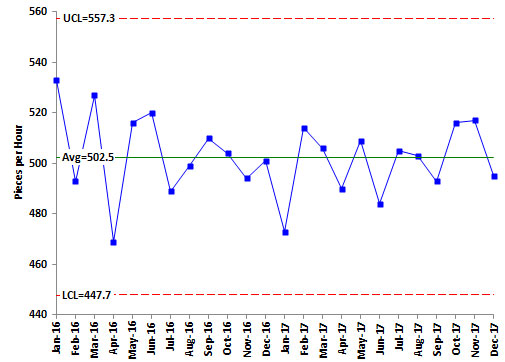

Figure 2 is the control chart with all the data. This process is in statistical control. So how do you go about improving the process?

Figure 2: Pieces per Hour Control Chart

If the workers could have reached the incentive goals on their own, they would have. The “how to increase” the pieces per hour is not known. The best proven way to work on this issue is through a team composed of those closest to the process as well as technical support people. The team needs to follow some problem-solving process (like Six Sigma) to work on the problem.

This approach will result in ways to improve the process. It always does. Hoping that people will work harder just because you dangle a carrot in front of them is just not going to work in most cases. You should use teamwork to find new ways to transform the process.

And what is a reasonable goal? Are the 510 and 525 reasonable goals for improvement from 500 pieces per hour? How do you use data to set a goal? A good rule of thumb for an improvement goal for a team is 0.5 to 1 standard deviations of what is being plotted. Return to Figure 1. The estimated sigma from the moving range chart (not shown) is 20.8. If you use 0.5 standard deviations, the goal would be 504.6 + (20.8/2) = 515 pieces per hour.

Summary

This publication has looked back at variation and the role it plays in determining how to improve a process. Simply setting goals and setting financial incentives rarely leads to lasting improvement. If a process has special causes of variation, the reasons for those should be found and eliminated. If the process only has common causes of variation – it is in statistical control, the process must be fundamentally changed. One of the best ways to do this is through the use of teams.

In this article, it is mentioned that as a thumb rule improvement goal for a team is 0.5 to 1 Standard Deviation. Thus I want to manually calculate the Standard Deviation. However I am not able to do so because the calculated goal of 515 pieces per hour is derived from the Figure 1. How can we calculate the same from Figure 1 as exact production numbers are not given .It would be great help, if you could guide me to calculating the score manually. My mail ID – archana.at@thalesgroup.com